Welcome to MTX

Industry world leader Provider of ripening systems Established over 25 years

We have been designing and installing ripening rooms for bananas, avocados and other tropical fruits for over three decades and are internationally recognised as a superior provider of ripening room technology.

We provide state of the art, highly efficient and easily maintained ripening systems tailored to suit our customers exact pallet configurations and capacity requirements.

About us

Innovation in Construction

MTX is a privately owned multi-disciplined engineering and solutions provider operating in a diverse range of sectors internationally.

We provide project services including pre-construction design, project management, technical advice and construction, to commissioning and ongoing maintenance services. We consistently promote innovation and sustainable energy efficient solutions

Our Services

System

Advantages

Service and Maintenance

Loblaws – 12 x 42 Pallet Banana Ripening Rooms

Loblaws awarded MTX with the contract to update the ripening rooms at their Boucherville Quebec distribution centre.

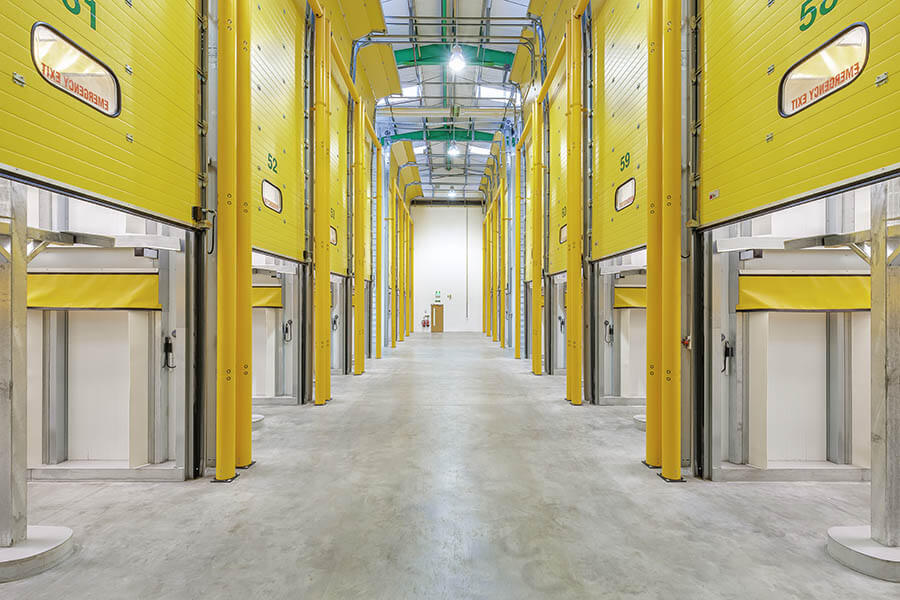

Winfresh UK – Ripening Rooms

Winfresh UK required extra capacity at their Stanstead location, in order to cater for their continued growth.

Van-Whole Produce – Banana Ripening Rooms

Van-Whole produce awarded MTX the contract to demolish their existing ten (10) 20-pallet ripening rooms and replace them with 15-21 pallet ripening rooms and 1-14 pallet ripening room.

Turner’s PPL – Tropical Ripening Rooms

Installation of two, 3-tier random access tropical ripening rooms and a 3-tier blast chiller for

Turners PPL at their ripening facility in Soham, Cambridgeshire.Save On Foods – 5 x 42 Pallet Banana Ripening Rooms

Save On Foods constructed a distribution facility in Acheson, Alberta. The facility was built by Norson Construction and consisted of 562,000 square feet of ambient and refrigerated warehouse space and offices.

MTX Ripening Rooms

Start a conversation

It would be great to help you with your next project.

Let’s discuss how we can assist with achieving your construction goals.

You can also request a call back, or click the button below for more ways to contact us.

What our clients think

Vernon Harris

MTX have been supporting Greencell with the provision of ripening rooms and facilities management services for nearly ten years. During this time they have always taken a proactive approach providing us with exceptional and reliable ripening roomRead more “Vernon Harris”